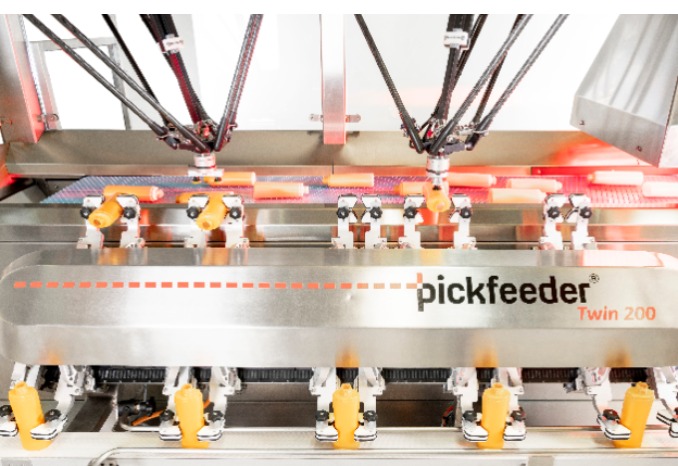

ROTZINGER concludes agreement with PACKFEEDER - ROTZINGER Group AG, Switzerland, has taken over PACKFEEDER SLU, Spain - Tomàs MULET VALLÈS, founder of PACKFEEDER, continues supporting the business - ROTZINGER is committed to further develop the business in the long term Terrassa, Spain, January 1st, 2022. ROTZINGER Group AG has taken over PACKFEEDER SLU. The two companies have reached an agreement to this effect. PACKFEEDER, founded in 2002 by Tomàs MULET VALLÈS, employs 22 people. Its product portfolio is specialized in the manufacturing of unscrambling machines. The company retain its well-known name PACKFEEDER and remains in its recently relocated headquarters in Terrassa close to Barcelona.